When it comes to understanding plastic, we consider ourselves to be experts in the use of thermoplastic materials… After all, Plas-Tech is the UK’s leading Thermoforming specialist!

We’re experts in our field and have a fantastic knowledge base of areas including:

- Vacuum Forming

- Injection Moulding

- In-House Tool Room

- CNC Trimming

- Value-Added Assembly

- 3D Printing

So, if you’re interested in learning more about thermoplastic materials and how we use them throughout our thermoforming manufacturing process, then we are your thermoforming specialist.

How are thermoplastics used for thermoforming?

We pride ourselves on our professional and personalised service, utilising our flexibility and expertise to complete the job at hand to the highest standard possible.

Whether our clients require a bespoke design, technical issues resolving, rapid prototyping or simply just a service they can rely upon… you can count on Plas-Tech to deliver!

This is all thanks to our incredible ability to handle and utilise thermoplastic materials for a range of thermoforming processes and technologies.

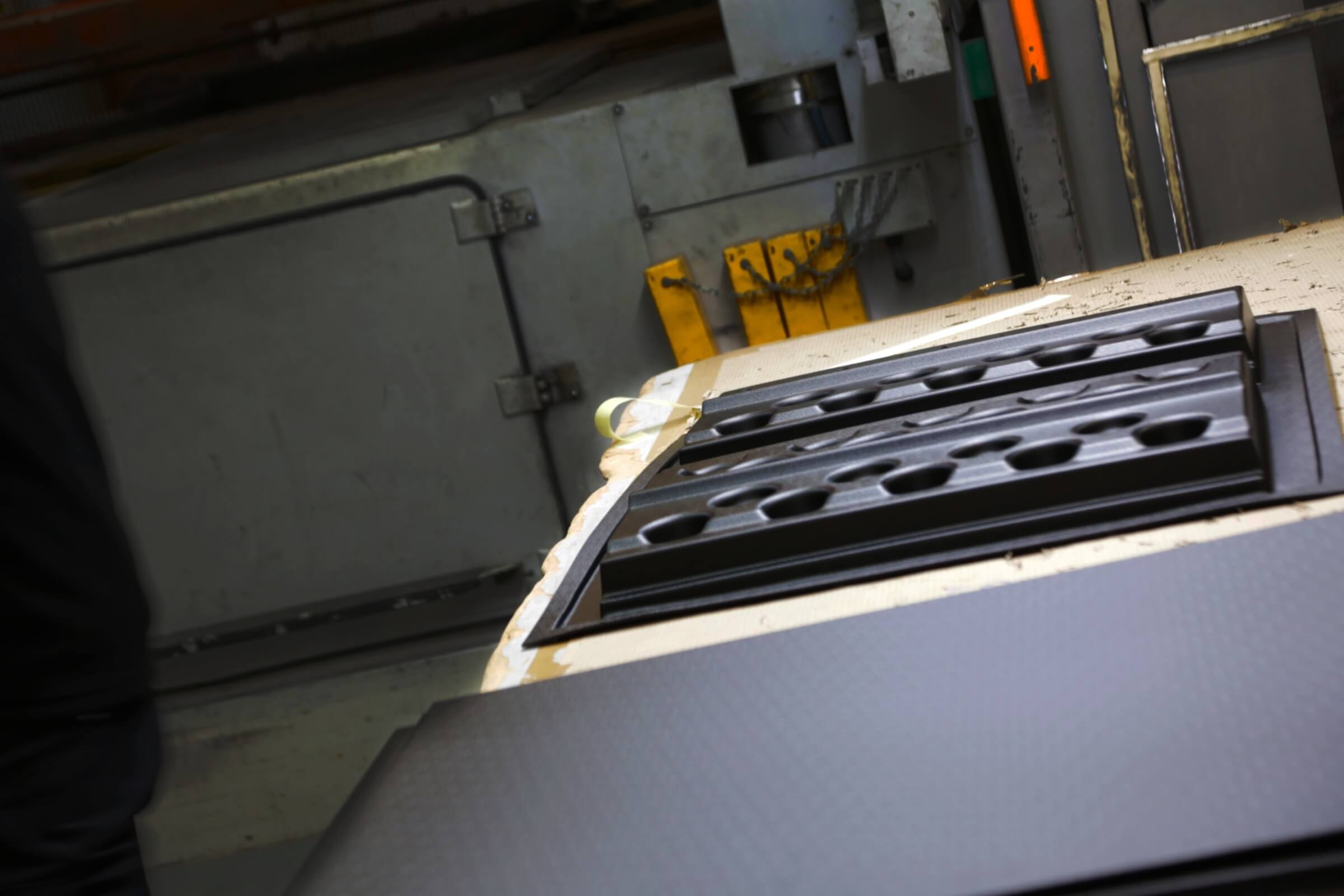

For example, our vacuum forming process comes with a range of technical capabilities, such as an automated loading process for volume production and 24/7 production times.

We can also handle mass volumes of thermoplastic materials using up to seven of our vacuum forming machines at a given time for up to 2.4 x 1.4m material, which gives us the ability to quickly manufacture both small and large components.

Thermoplastic materials used can include ABS, Polypropylene, HDPE, Polycarbonate, and most commonly High Impact Polystyrene Sheeting (HIPS).

These materials can have custom colours, textures and finishes such as high gloss, soft feel and decorative foils.

What is thermoforming?

Thermoforming is the process of heating a thermoplastic sheet to a certain elevated temperature which allows the material to become soft.

The sheet is then stretched across a single-sided mould and manipulated until the desired shape is reached, then left to cool and harden into the final form.

What is a thermoplastic and why is it used?

Thermoplastics, otherwise known as thermosoft plastic, is a plastic polymer material that often has a high molecular weight, which increases the material’s impact resistance.

This allows the material to be manipulated multiple times without changing the material’s chemical property, and also gives it the “memory” to return the material to its original shape when reheated.

The benefit of this material for the use of thermoforming is that thermoplastic materials are incredibly pliable/moldable once a certain elevated temperature is met.

Mainly because of the fact they’re made up of polymer resins which allow them to be soft when heated, hence the name “thermosoft” plastic.

And to those more interested in the science of it all, when heated, thermoplastic materials actually become homogenised liquid; giving them the ability to be reshaped and sized, which is why they’re used for processes such as injection moulding.

Using a material that’s pliable is a great, sustainable source for thermoforming, as it means we can reduce the amount of material waste.

Plus, thermoplastic materials can be moulded around wood, structural foam, casts or machined aluminium moulds, allowing them to be moulded into almost any shape!