Thermoforming is the process of heating a thermoplastic material and then shaping it using a mould to create a part. It’s an essential part of modern society and is used in a huge range of applications all around us. One of the most integral parts of any thermoforming process is the tooling process, when tooling is correct, it will ensure consistency between angles, lines, textures and shapes from one piece to another. Here at Plas Tech, we’re proud to boast about our in-house tool room, but what are the benefits of it?

What is In-house Tooling?

When it comes to thermoforming projects, different and unique tools are often needed and vary significantly from project to project. This essentially means that in order for the final project to be created and completed, the first step is to create the tool/tools needed for its production.

Typically, within our industry, companies rely on the help of third-party toolmakers which can add an array of potential complications, timings and costs within itself. By using our in-house tool room, the third-party function is removed, making the whole process smoother and easier. Here are the benefits of using a thermoforming company with an in-house tool room.

Benefits of In-house Tooling

There is a wide range of benefits to choosing to use an in-house tooling thermoforming company. Not only will it have environmental benefits in reducing delivery transits but it can also save your business money. Here are some of the benefits of in-house tooling.

Cost Efficiency & Cost Savings

As previously mentioned, in-house tooling removes the third-party aspect. If you were to use a company without an in-house tool room, you need to work within the third-party schedule, this can have additional effects on your project. You’ve also got to remember that the third party will also need to make a profit, making it an even more costly process.

Quicker Turnaround Times

An in-house tool room eliminates the reliance on external vendors and factors, this can save you money on things such as extra delivery, processing, amendments and corrections. By eliminating the need for a third-party company, you can expect quicker project turnaround times. We can further prioritise your projects and move around our schedules to suit you.

Enhanced Design Control, Flexibility & Communication

Without the need for a third party, communication is increased significantly meaning you’re able to talk directly with our team to get the perfect tool, our technicians and engineers are also able to directly advise you on adjustments and changes that may be necessary. In-house tooling will also give you more freedom to control, customise and experiment with your tool design. Our team of technicians are happy to work closely with you to ensure the final tool is exactly what you want and require. If you receive your tool and believe something needs slightly changing, we’re happy to accommodate fixes and changes.

Access to a Full Service Range

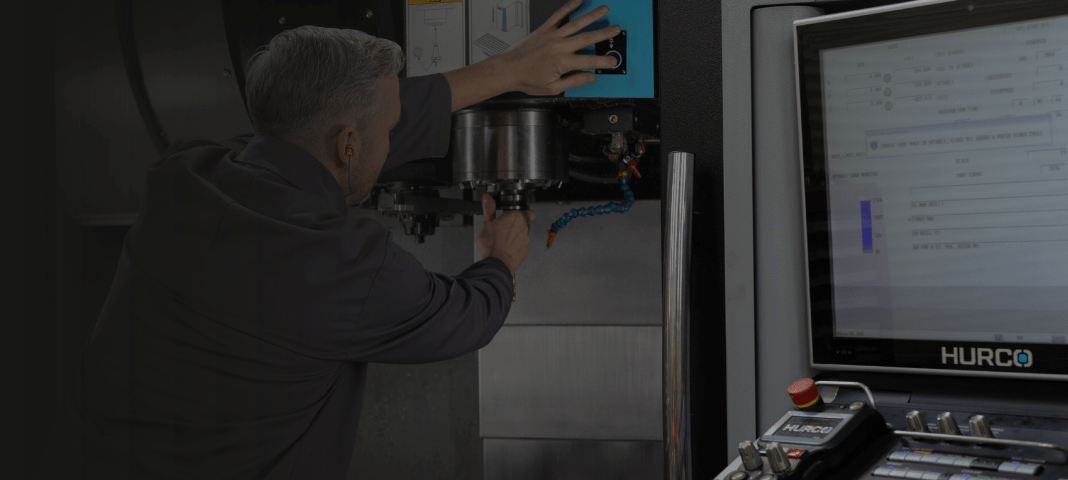

At Plas Tech, we’re proud to be able to offer a full in-house tooling service range, incorporating the latest technology with our incredibly experienced team. Our full range of in-house tooling services includes everything from tooling development and tool repairs to reverse engineering.

Working with Plas Tech Thermoforming

At Plas Tech, we’re the only fully independent thermoforming specialist manufacturing offering a full range of services, including:

- Vacuum Forming

- Injection Moulding

- CNC Trimming

- Value Added Assembly

- 3D Printing

- In-house Tooling

If you’re looking to improve your efficiency when it comes to creating and assembling new tools for your parts, don’t hesitate to get in touch with our team today.