Vacuum forming is one of those manufacturing methods that often flies under the radar. Most people have seen hundreds of vacuum formed products without even realising it. From your car interior to the packaging in your fridge, vacuum forming quietly shapes the world around us.

At Plas-Tech, we’ve been producing high-quality vacuum formed products for over 30 years. Our vacuum forming services support industries across the UK, creating everything from industrial components to custom retail displays.

That being said, we want to reveal a few everyday items that owe their form and function to this clever process.

Automotive Interiors

If you’ve ever stepped into a modern vehicle, you’ve been surrounded by vacuum formed products. Many interior panels, dashboards, and storage components use vacuum forming because it produces strong, lightweight parts that fit precisely. The smooth finish and easy colour matching make it ideal for car interiors, motorhomes, and caravans.

Medical Equipment

Clean, hygienic, and easy to shape, vacuum forming suits medical environments perfectly. Many hospital trays, machine housings, and protective covers start as flat sheets of thermoplastic. Our vacuum forming services help medical manufacturers achieve parts that meet strict hygiene and performance standards.

Retail & Point of Sale Displays

That stylish product stand or branded display you saw at the shop? It was likely vacuum formed. The process creates durable, visually appealing units that can hold products securely whilst showcasing branding. Vacuum formed displays are lightweight and affordable to produce in high volumes.

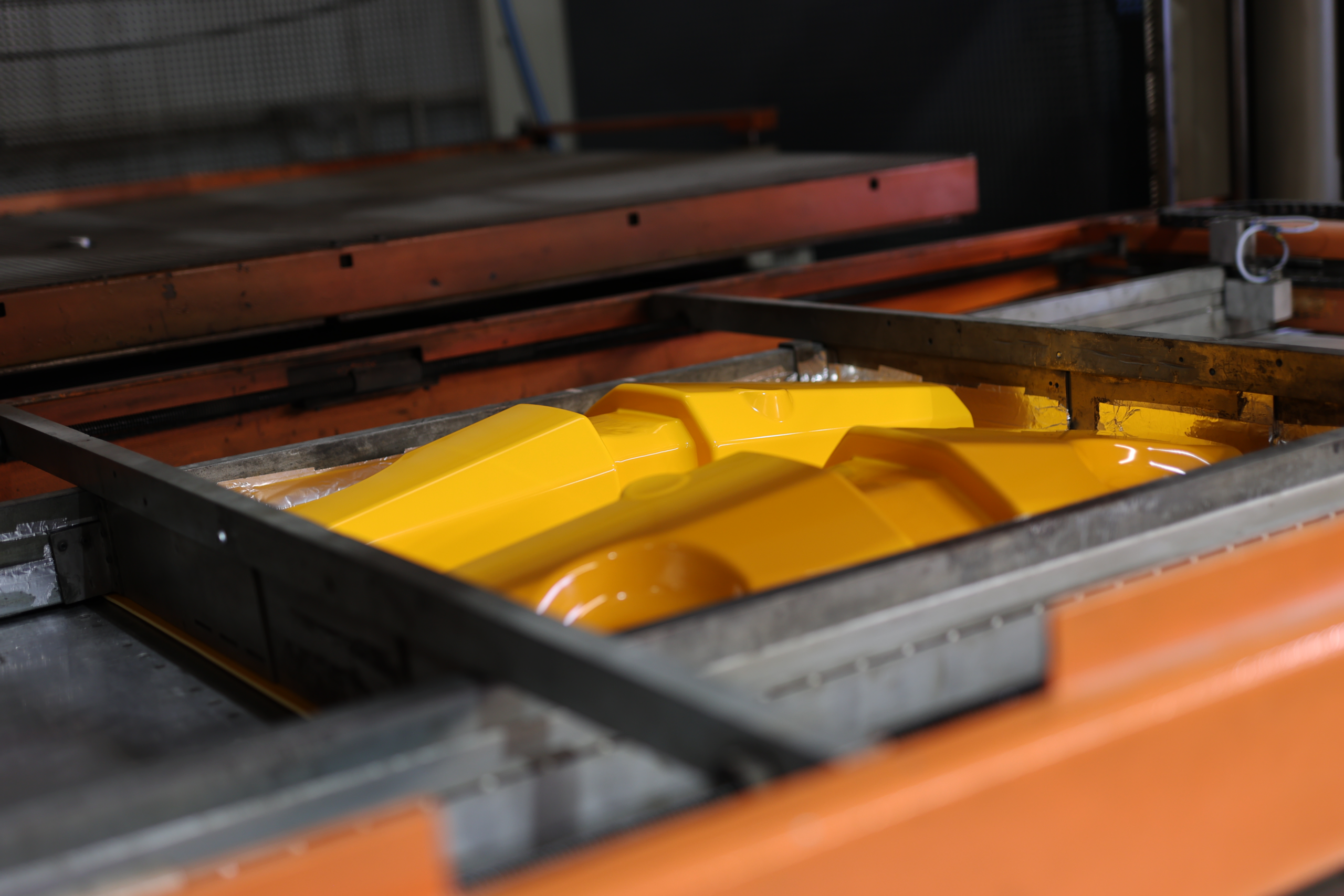

Construction & Industrial Panels

Vacuum forming doesn’t just create neat retail items; it also shapes rugged components for heavy-duty use. At Plas-Tech, we supply vacuum formed products for construction equipment and industrial machinery. The process allows us to form tough housings, guards, and covers that can handle daily wear and tear.

Refrigeration & Appliance Parts

Many modern fridges and freezers rely on vacuum formed parts. The crisp inner panels and shelves are often formed from ABS or HIPS plastic. This gives them a smooth, easy-clean surface and strong structure without adding unnecessary weight.

Leisure & Transport

From motorhomes to trailers, vacuum formed products appear in many leisure vehicles. The process is ideal for shaping interior fittings, storage units, and external trims. It’s flexible enough to handle both small batches and large production runs, which suits the variety in the leisure market.

Packaging You Use Every Day

Vacuum forming isn’t just for big components. It also makes everyday packaging like plastic trays, inserts, and protective shells. These lightweight forms keep products safe during transport and help create a professional presentation.

Why Choose Plas-Tech for your Vacuum Formed Products?

We handle every stage of production in-house, from design to tooling, forming, and finishing. That gives you greater control and shorter lead times across every project.

If you’re looking for a partner who understands vacuum forming products inside and out, we at Plas-Tech can help. Our vacuum forming services combine precision and flexibility, backed by over 30 years of experience.

Get in touch with our team today and see how we can bring your vacuum forming products to life.