At Plas-Tech, we are experts in the plastics behind vacuum moulding. Whilst many know about the process itself, there’s more to understand about the sheets we use, how they behave, and what makes one plastic better than another for vacuum forming.

That being said, let’s take a look at the plastics at greater depth…

Why Material Choice Matters

When we choose plastics for vacuum forming, we look at the job your part will face. Some parts need strength. Some need a smooth finish. Some need flexibility or heat resistance. Once we know your environment and your goals, we pick the right sheet and guide you through the options.

Common Plastics for Vacuum Forming

Here are the vacuum formable plastics we use the most when we create products for our customers:

ABS for Strong, Tough Parts

ABS works well for tough parts that take knocks. You often see it in automotive panels or industrial covers. It gives a clean finish and holds colour well. Choose ABS when you need a reliable, durable plastic for vacuum forming.

HIPS for Displays and Packaging

HIPS suits point-of-sale work and packaging. It cuts cleanly and prints well. If you need lighter parts or a cost-effective option, HIPS often sits at the top of the list.

Polypropylene for Flexibility

Polypropylene bends without breaking. It works well in parts that need repeated flex. You also get good chemical resistance. Use it when you need a balance of strong flexibility and low weight.

HDPE for Hard-Wearing Components

HDPE handles impact and moisture without issues. You see it used in handling equipment, heavy-use trays, and outdoor parts. It gives consistent results during vacuum moulding, which keeps quality steady across large production runs.

Polycarbonate for Demanding Environments

Polycarbonate offers serious strength and high heat resistance. If you need clarity or a near-unbreakable finish, this is the right option. It has a slightly higher price point, but it handles demanding environments with ease.

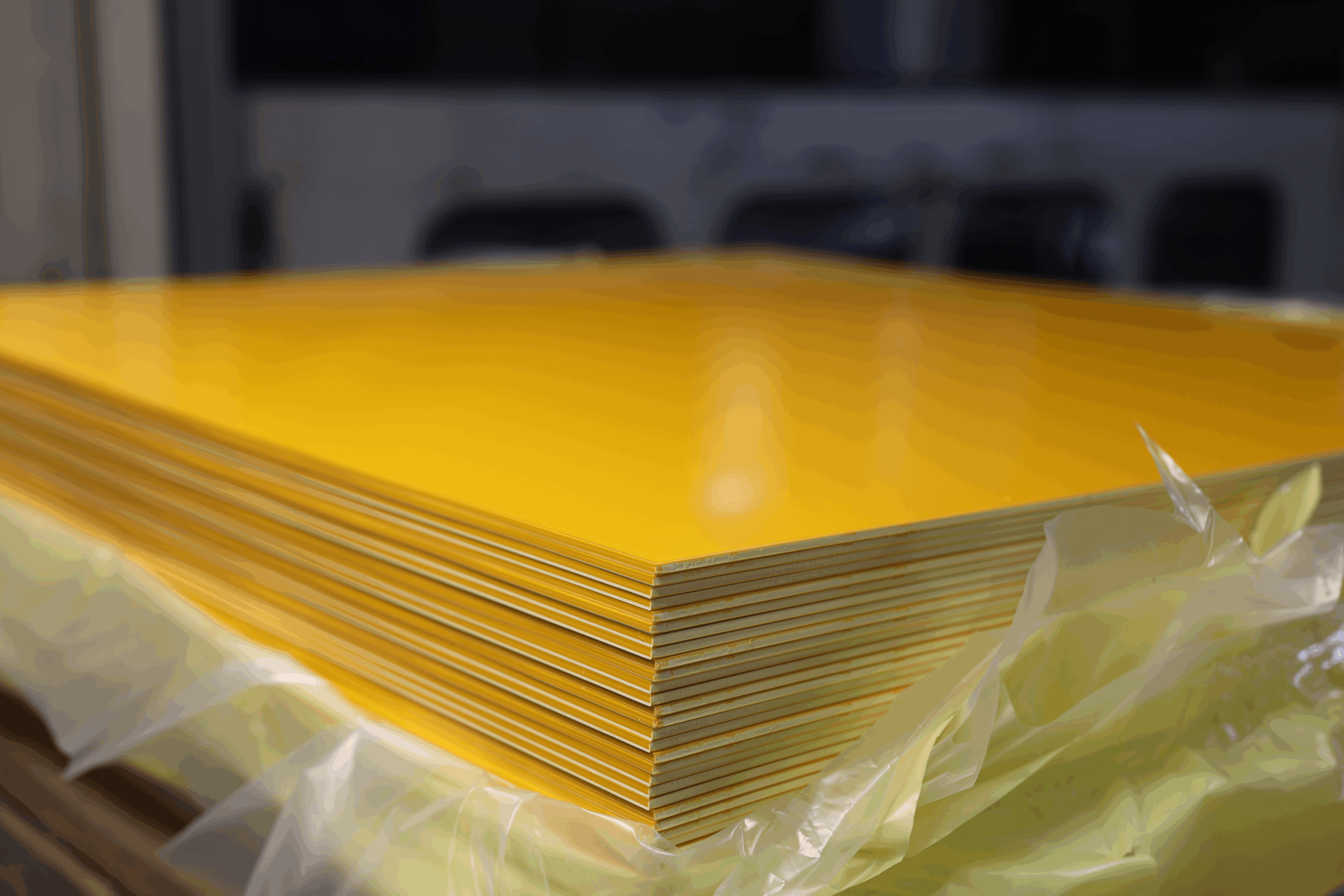

Finishes, Colours, & Textures

We also help customers compare textures, colours, and finishes. That includes high gloss, soft-touch, or decorative foils.

What to Think About When Choosing Material

If you’re new to choosing plastic for vacuum forming, here are a few quick things to keep in mind:

- Think about temperature, impact, and wear

- Decide if you need colour-matched

- Ask about weight, rigidity, and finish

- Check how the part will be trimmed or assembled

- Share any issues from past parts you want to avoid

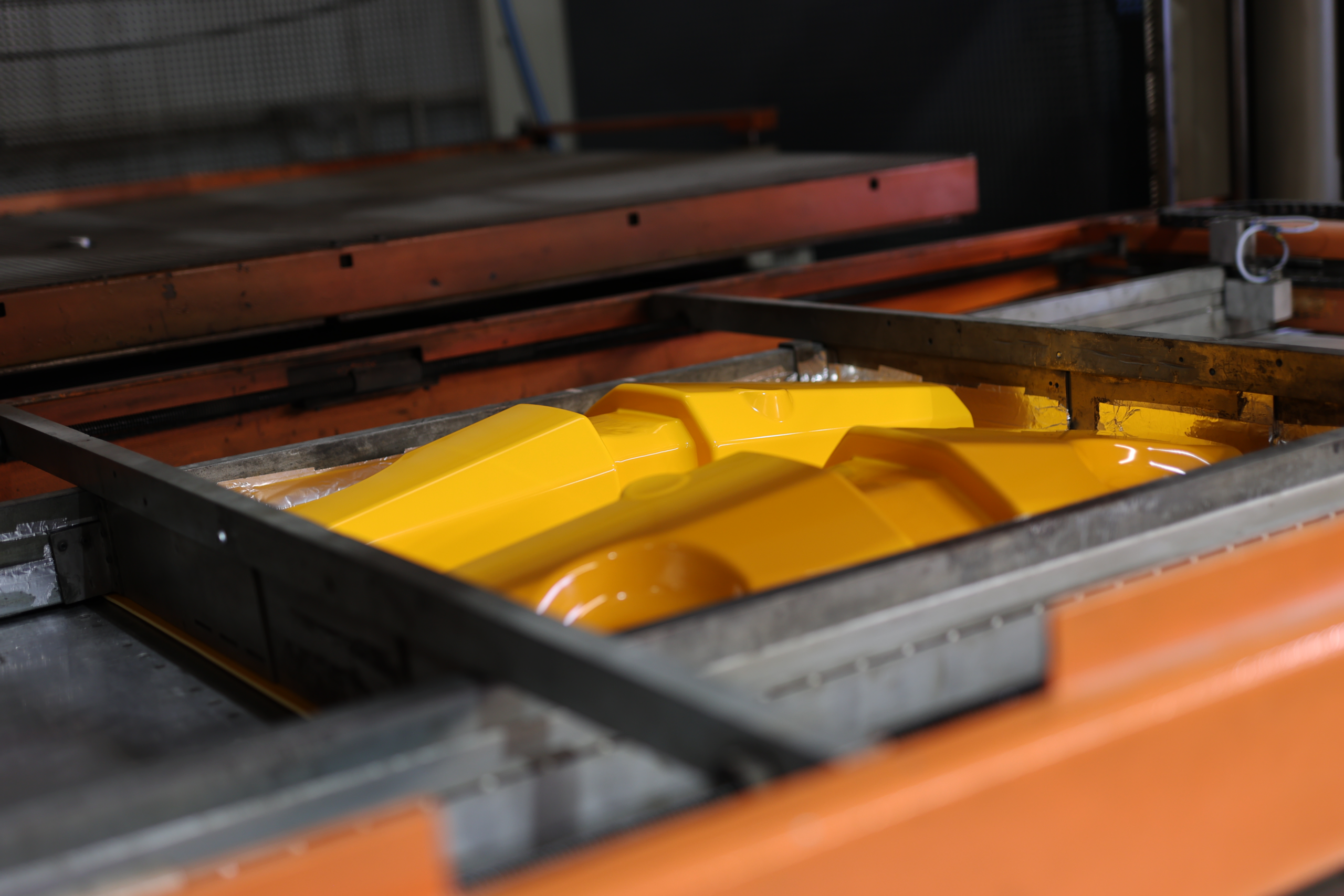

How We Help You Pick the Right Plastic for Vacuum Moulding

When you work with us, you don’t need to know every detail from day one. We guide you through it and help you pick the right vacuum formable plastics for your design and your environment. Our team handles tooling in-house and tests material choices early, so you see how things look and behave before we move into full production.

Talk to Us About Your Next Vaccum Forming Project

If you want to talk through a new project or need help choosing plastic for an existing design, get in touch with our team. We’ll walk you through the options and help you get the right material first time.