At Plas-Tech, we know pressure moulding inside and out. As a trusted pressure moulding company, we’ve spent years refining our processes. Pressure moulding helps us create strong, detailed plastic parts.

Let’s explain how it works, why it matters, and how our team brings it all together.

What Is Pressure Moulding?

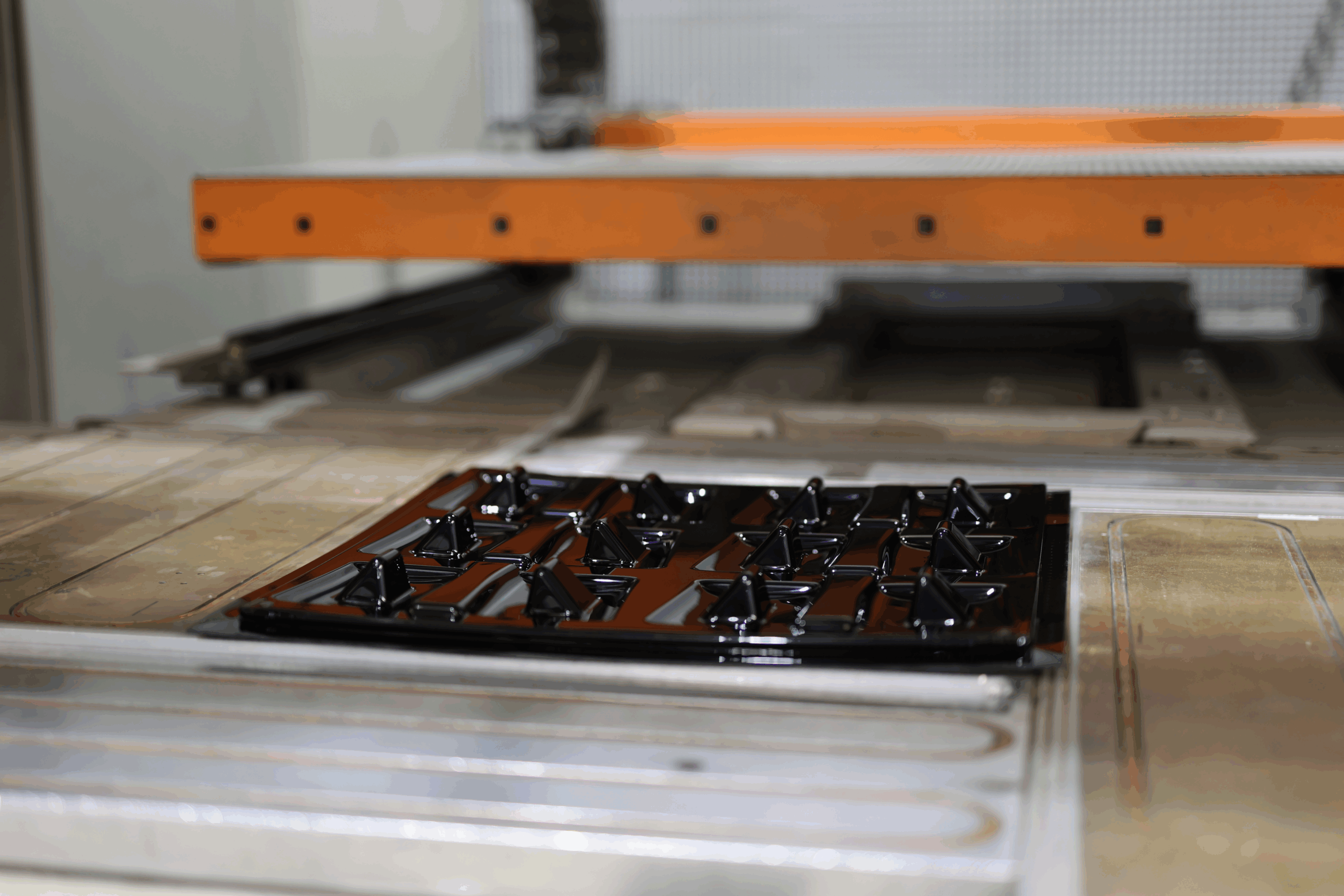

Pressure moulding is a type of plastic forming. It uses heat and pressure to shape plastic sheets or pellets into precise forms. The process works well for making strong, durable parts with clean finishes.

Here’s how it works at Plas-Tech:

- We heat a plastic material until it becomes soft.

- We press it into a mould using high pressure.

- The mould shapes the plastic exactly to your design.

- Once cool, the part keeps its new form.

This method gives us detailed control over every part we make. It also lets us form plastic quickly and efficiently.

Why Pressure Moulding Works

As plastic forming manufacturers, we use pressure moulding when we need:

- High strength and rigidity

- Consistent quality across batches

- Fine surface finishes and complex shapes

Pressure moulding also reduces waste. Because we press material into exact shapes, there’s little trimming required. That means lower costs and better efficiency for our clients.

Our Process at Plas-Tech

Here’s how we approach pressure moulding:

- Design Support

We help you shape your idea into a working model. - Tooling & Moulds

We build custom tools in-house for perfect fits. - Material Advice

We guide you to the right plastic for your needs (ABS, polypropylene, or others). - In-House Prototyping

Our Ureol prototypes let you test designs fast. - 24/7 Production

We run around the clock to meet your deadlines.

Why Choose a Pressure Moulding Company Like Plas-Tech?

Working with a specialist pressure moulding company brings clear benefits:

- Faster turnaround times with in-house production

- Reduced risk thanks to technical support at every step

- Access to advanced machines and materials

- High-quality finishes with tight tolerances

Our clients span industries, from automotive to medical to retail. No matter the product, we bring the same level of care, speed, and expertise.

Pressure Moulding for Your Projects

Pressure moulding may sound technical, but it’s just one of the many tools we use to shape your ideas into real-world products. At Plas-Tech, we treat every project with care and precision. As one of the UK’s leading plastic forming manufacturers, we’re proud to deliver smart solutions that meet your needs.

If you’re planning a new product or need a custom plastic part, get in touch with us.