At Plas-Tech, we get lots of questions about vac forming. It’s a smart, cost-effective way to make plastic parts, but if you’re new to it, it can sound confusing. We’ve pulled together some of the most common questions we hear and answered them in simple terms.

What is vac forming?

Vac forming (short for vacuum forming) is a method of shaping plastic. We take a flat sheet of thermoplastic, heat it, then pull it over a mould using vacuum pressure. The plastic cools and sets in the shape of the mould.

It’s quick, affordable, and works for lots of different industries. At Plas-Tech, we use vac forming to make parts for vehicles, shower trays, packaging, and more.

How does vac forming work?

There are three main steps:

- Make the mould

We start by creating a mould in the shape you need. This can be made from wood, aluminium, or high-temp plastics. We use aluminium when durability and fine detail matter. - Heat and form the plastic

We heat the plastic until it softens. Then we place it over the mould. The machine removes the air and pulls the plastic tight to the mould. - Cool and trim the part

After the plastic sets, we remove the mould and trim the part. We also cut or drill where needed.

What types of plastic can you use?

We use several kinds of plastic, depending on what the part needs to do. Here are the most common ones we use at Plas-Tech:

- ABS

- HIPS

- Polycarbonate

- HDPE

- Polypropylene

Each plastic has different strengths. For example, ABS is tough and impact-resistant. Polycarbonate is great for clarity and strength.

Can you handle large production runs?

Yes. Our vac forming machines run 24/7 and can handle anything from 200 to 40,000 parts a year. Our biggest machines mould up to 2.4 x 1.4 metres, which gives us a lot of flexibility.

What finish can I get?

You can choose from a wide range of textures and colours. We offer high gloss, embossed, soft-touch, and decorative foils. We also stock many colours and can work with custom colours too.

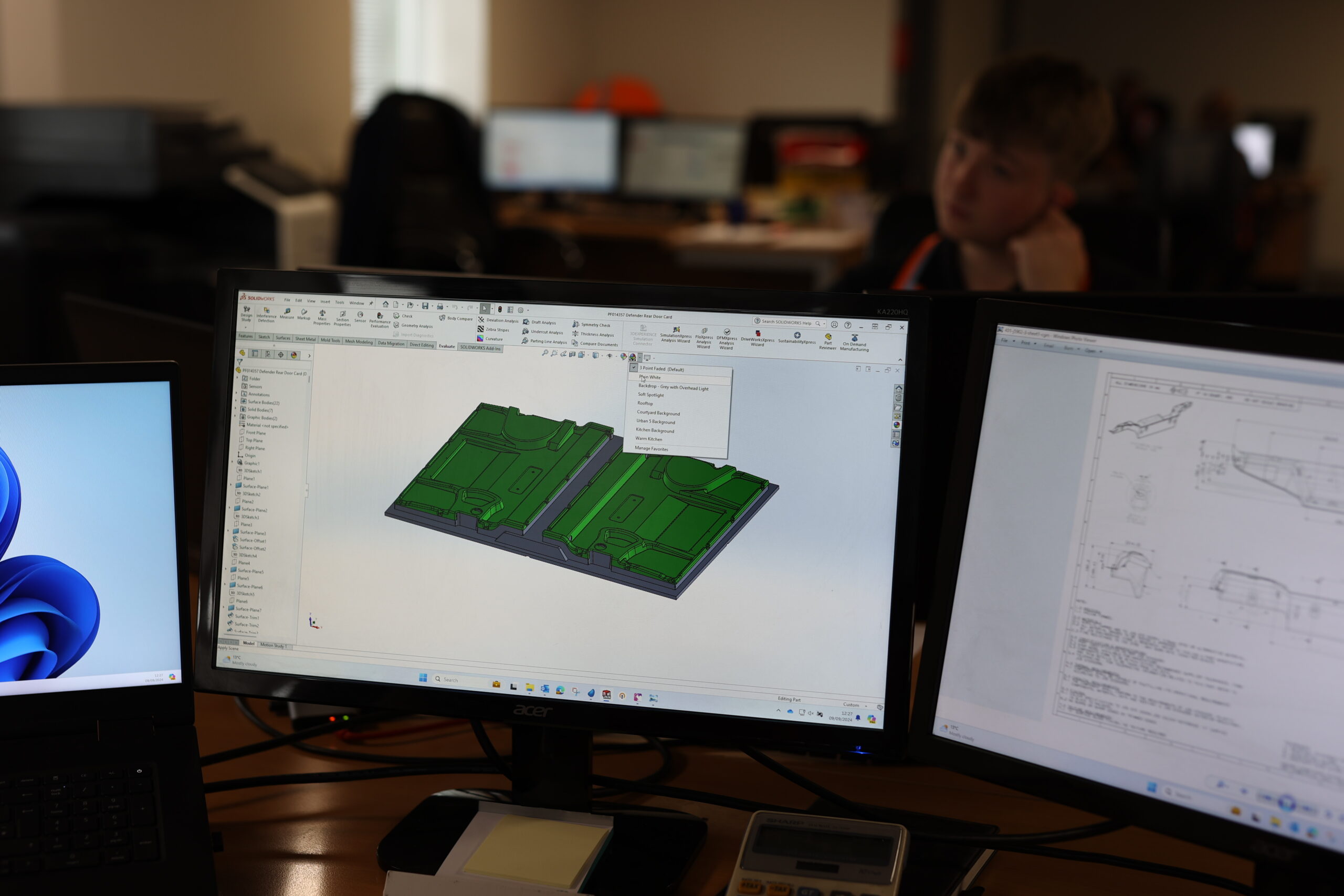

Do you help with design?

Absolutely. We have a team of experienced designers and engineers who will help you create the right product. We can offer CAD designs, prototypes, and even toolmaking in-house. Our Ureol prototyping is fast and affordable, which helps you see the final part before we move to full production.

Why choose Plas-Tech for Vac Forming?

We’ve been in vac forming for years and know what works. Our team is hands-on, friendly, and always ready to solve problems. We run a tight, efficient shop with ISO 9001:2015 certification. You get high-quality parts, fast turnaround, and a service you can trust.

Got more questions about vac forming? Reach out to our team.